Development and qualification of specific NDT equipment: Using our expertise to work for you

The operations and development teams at Intercontrôle can call on their exceptional experience and expertise that is continuously maintained. They make Intercontrôle a valued partner capable of adapting to all inspection codes in force worldwide (RSE-M, ASME, KTA) and of offering a rapid response to the demands of its customers in France and the world over.

The demands for longer reactor lifespans and shorter and less expensive interventions are also a permanent incentive to develop new inspection equipment.

Our highly varied developments demonstrate our capacity to innovate.

Some of our developments:

- The in-service inspection machine (MIS) used to inspect the reactor pressure vessel of the Flamanville 3 EPR

- The EXACT inspection chain that uses eddy current testing to inspect steam generator tubes

- Ultrasonic inspection of the reactor vessel inner radius nozzles

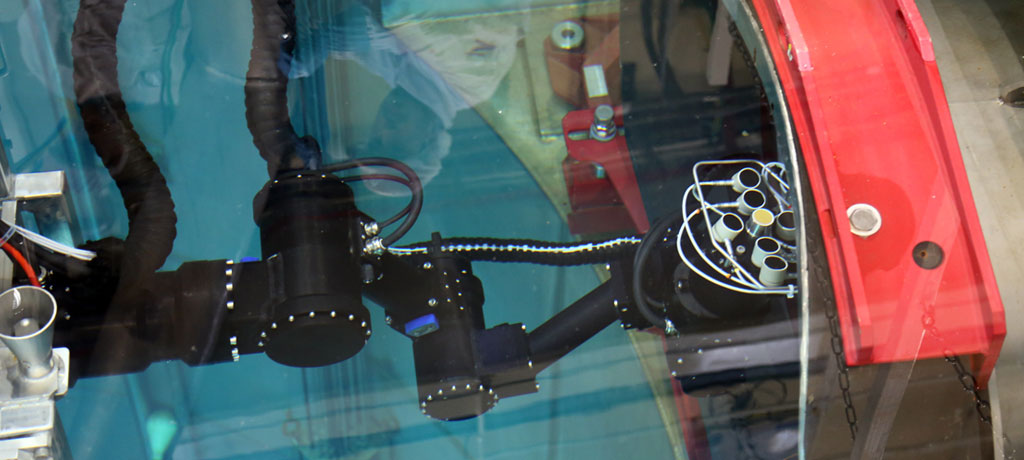

- Ultrasonic and televisual inspection of reactor vessel bottom-mounted instrumentation (BMI)

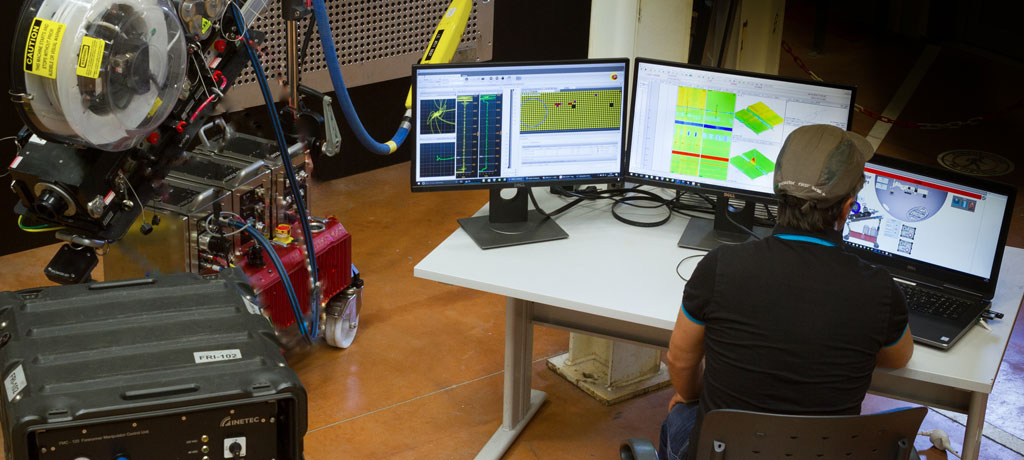

- Phased-array ultrasonic robotic inspection systems for primary circuit piping

- Remote control system for the inspection of a primary circuit nozzle with a flexible phased array ultrasonic transducer

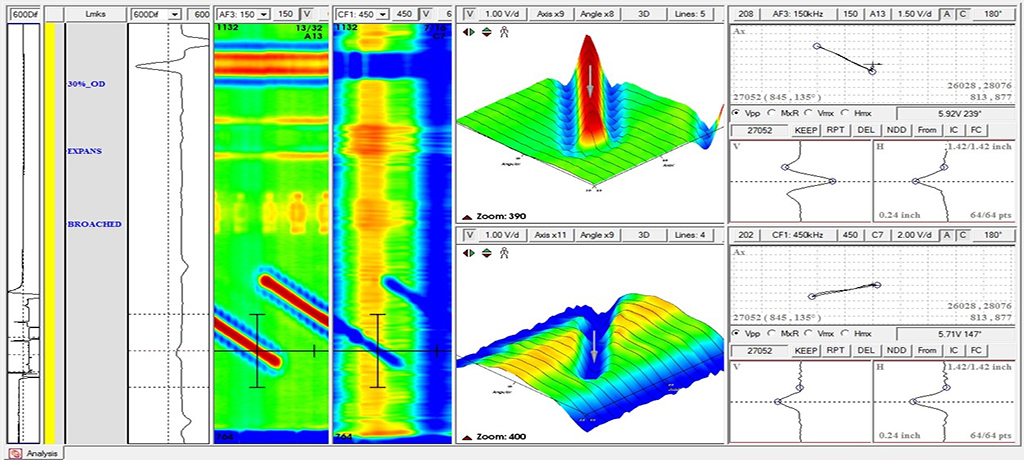

- Data processing software

-

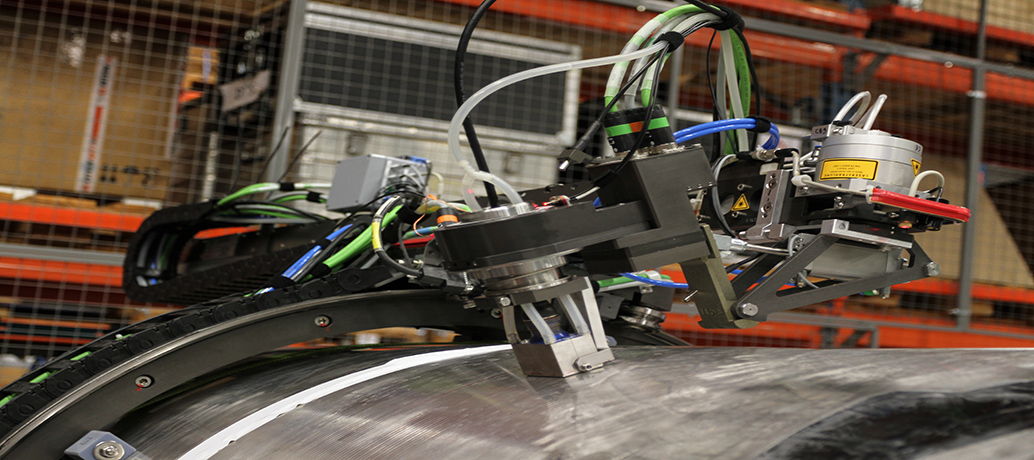

Contrôle de soudure sur une tuyauterie primaire

Piping weld inspection on the EPR Flamanville 3 main coolant line

-

-

-

-